When dedicated dies don’t make sense

Have you ever needed only a small number of sheet-metal parts,

but found that making dedicated dies was simply too expensive or time-consuming?

This situation is common for prototypes, limited production runs, and replacement parts after mass production has ended.

In such cases, incremental forming offers a practical alternative.

Incremental forming is a sheet-metal forming process that does not require dedicated dies, allowing parts to be manufactured directly from digital data.

What is incremental forming?

Incremental forming is a process in which a rod-shaped tool gradually presses a metal sheet along a programmed tool path, forming the desired shape step by step.

Unlike conventional press forming, the material is not shaped all at once using a fixed die.

Instead, deformation is applied locally and incrementally until the final geometry is achieved.

Because the shape is defined by data rather than tooling, the same machine can produce many different shapes, simply by changing the forming program.

It may be difficult to fully visualize this process from words alone.

To better understand how incremental forming works in practice, the following videos provide a clear and intuitive demonstration of the forming process.

Demonstration video showing the incremental forming process(Youtube)

Why incremental forming is useful

Incremental forming is particularly effective in situations such as:

-

Tooling cost cannot be justified

-

Only a small quantity of parts is required

-

Prototypes or trial parts are needed

-

Design changes are expected

-

Replacement parts are required after mass production has ended

In conventional press forming, each part requires its own dedicated die, resulting in a one-to-one relationship between part and tooling.

With incremental forming, however, one forming system can support many different parts, making it well suited to high-mix, low-volume production.

The challenge of vertical walls

One well-known limitation of incremental forming is the difficulty of producing vertical or near-vertical walls.

As the wall angle becomes steeper, the material must stretch over a very short distance.

This localized deformation often leads to excessive thinning and, ultimately, material fracture.

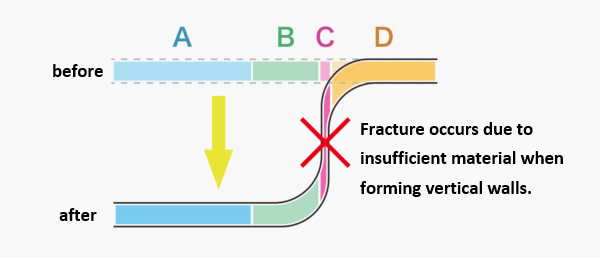

Figure 1. Mechanism of fracture during vertical wall forming in incremental forming.

When material supply is insufficient in the vertical wall region, excessive stretching occurs locally, leading to fracture.

For this reason, many incremental forming processes avoid shapes that include vertical walls.

Our approach: forming vertical walls without dies

Through our own process design and accumulated forming know-how, we have addressed this limitation and made it possible to form practical shapes that include vertical walls, even without dedicated dies.

An example of an actual formed part with vertical walls produced using this approach is shown below.

Figure 2. Examples of sheet metal parts with vertical walls formed by incremental forming without dedicated dies.

These parts demonstrate the capability to produce practical three-dimensional geometries using our proprietary forming approach.

At first glance, these metal parts may appear to have been produced by conventional deep drawing using dedicated dies.

However, it is important to note that all of these parts were formed without dies.

This capability is not a standard feature of incremental forming.

It is achieved by optimizing the forming strategy based on real production experience, rather than relying on theoretical conditions alone.

As a result, the range of parts that can be produced by incremental forming is significantly expanded.

The photograph below shows a variety of parts formed by incremental forming, demonstrating the wide range of geometries that can be produced using this process.

Figure 3. Examples of sheet metal parts formed by incremental forming.

As shown, a wide range of shapes and geometries can be produced without dedicated tooling, highlighting the flexibility of the process.

These examples show that incremental forming is not limited to a specific shape or application.

By adjusting the forming program, a single setup can accommodate a wide variety of part geometries.

Proven in actual product use

This is not a trial-level or experimental technology.

We actually use incremental forming to manufacture replacement parts for our own branded products, where low-volume production and long-term parts availability are critical.

Using the process in real products allows us to continuously refine forming conditions and ensure stable, repeatable results.

An example of replacement parts for our own branded products, manufactured using incremental forming, is shown below.

Figure 4 Replacement parts for our own branded products manufactured using incremental forming.

These parts are produced in multiple quantities to support long-term service and parts availability without dedicated tooling.

When should you consider incremental forming?

Incremental forming may be a good option if you are thinking:

-

“We don’t need thousands of parts.”

-

“The tooling cost doesn’t make sense for this volume.”

-

“This is a prototype, limited run, or service part.”

-

“The shape might change in the future.”

If these points sound familiar, incremental forming could be worth considering.

Let’s discuss your part

If you are wondering whether incremental forming could work for your specific part,

feel free to share your drawing or requirements with us.

We are happy to discuss feasibility from a manufacturing and engineering perspective,

and help you determine whether this process makes sense for your application.

For inquiries or technical discussions, please contact:

Tsubasa Fujii

Email: t.fujii@e-fujii.co.jp

This blog is operated by Fuji Corporation, a Japanese manufacturer specializing in snow blowers and brush cutters.

In addition to developing and manufacturing our own products, we apply our forming technologies directly in actual production environments.

For more information about our company and products, please visit our official website:

https://www.e-fujii.co.jp/eng/index.html